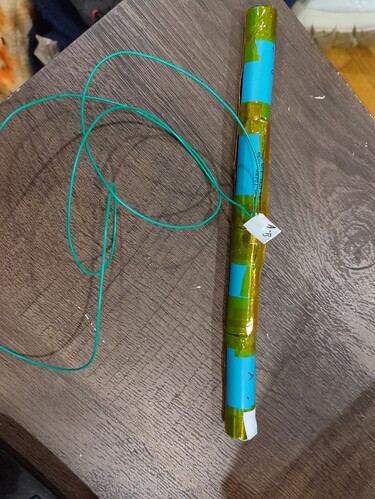

I have a battery stick!

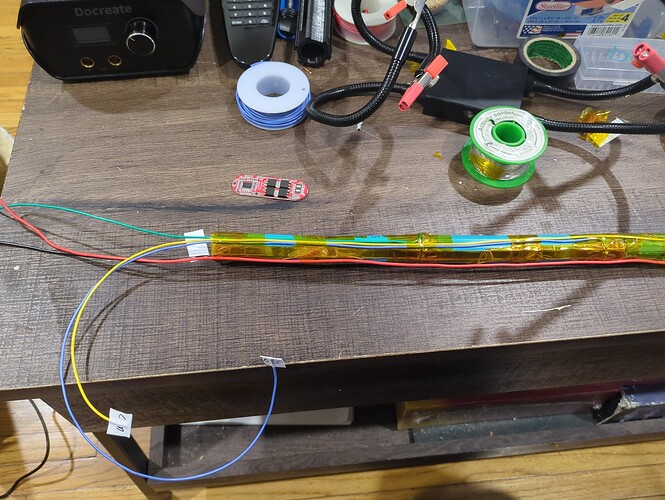

So the wires are way longer than they need to be. Way longer. Considering that I don’t have finalized 3D prints to hold the BMS and rest of the bits, I’m OK with that.

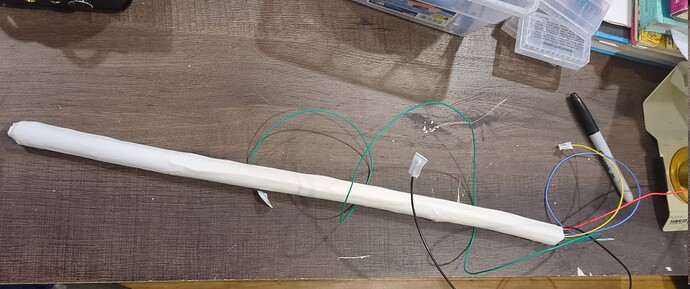

Added a small bit of stick on foam on the top and bottom, in case there’s some vertical impact, to give it a bit of cushion. Makes it a bit longer, as does the heatshrink. Although I probably can trim a touch of that off. Still works out to just about what I expected, within a few millimeters, which is pretty great.

And unfortunately it’s going to be raining for the next few days, so my intention to print in ABS and acetone finish to increase the edges of the layer bonding can’t be done, since that should be done outside.

So in short, it’s progressing. I did do a quick test print in PLA of a part fitting around the stick to keep it centered, but looks like I’m going to need to make a whole bunch of individual custom fit/designed bits, because of the varying wiring and nickel strips between parts.

All the wires are labeled, which 2 cell groups are on either side of it, so it’ll be easy to match up to the right BMS location. And I checked the Pos and Neg ends, reads something like 12.3-12.4v. Right about what it should for 4 cell groups, with the cells being a touch over 3v each before starting assembly.

The 2nd 2 cell groups went a lot faster, with experience gained with the first pair.

I think v3 (or v2.5) I’m actually going to do up a PCB and get it printed with various MOSFET controls, and bucks for each LED strip, separate LDO/buck for the ESP32, that sort of thing. Probably get the length down a LOT. Speaking of which, I’m probably going to need to remove a lot of the vertical inter-part height on my current prototype pieces. I think I’ve left too much room for most of them. Slightly easier to put together is nice, but I think I actually need to claw back some centimeters of height in order to fit it all. Plus I need to do some kind of bottom foot. Contemplating getting a few bits of nice hardwood, different colors, and use my router to give them some turned wood look, somehow, something more than just a straight round that fits over top of the bottom of the cane as a foot. Hm, some rock maple might be sturdy enough to be used. Or maybe one of these swivel feet from McMaster. Decisions decisions…