So I recently found WLED, a great F/OSS project for ESP controllers to control addressable LED strips/matrixes. Really cool features. And then I found Sound Reactive WLED fork, which makes it even cooler! Get ambient audio and have the FFT/etc already built into the code, with some preset color/animation choices which means I don’t have to try and be creative about that, which is not my strong suit. The SR WLED is for ESP32 only, but those are still generally relatively cheap and plentiful, and you can find various boards pre-flashed with WLED, including some with onboard mics. Nice!

Links to LedBox V2, which can be bought from tindie. Good hardware, good documentation, everything open source including design files. Basically everything you’d want from a hobbyist who saw a niche and felt like helping out folks and maybe even making a few $. Nice! Even has a resettable fuse for when powering LEDs through the device, and a proper buck-boost so you can power the board and LEDs up to 17v max. Needs LED voltage, so 5v/12v will be the most common.

Then while on Tindie I found this slightly cheaper version, that actually is thinner, although a bit longer, but will work better for 1 of my use-cases. Just thin enough, yay!

So I’ve got both, do some very basic tests with ambient music and an LED strip connected to each. Yup, works! The WLED Sync code (over WiFi UDP) also works, super sweet. So I can have one be the “primary” in AP mode on startup, and I power the other one up after and set it to the AP from the primary, and then they’ll sync animations and such, but when far enough away that the AP disconnects, it’ll fall back to it’s own thing.

However it was very obviously Chinesium, and it does have some issues. Takes forever to boot up. I’ve been trying to get serial commands working with the SR WLED 0.13.1 pre-release, and for some reason it just isn’t working (we actually think we’ve found the issue in the SR code, will test it out later tonight), so I ended up hooking up the Chinesium one to serial. Power it up, and I’m getting Brownout looping reset. Great. Talking with the seller, at least they’re fairly responsive which is nice, get down to the crux of the real issue.

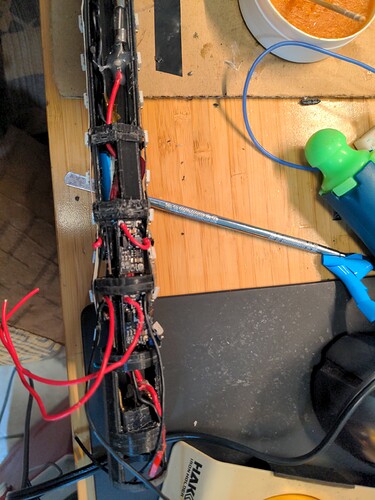

Apparently the thing was originally designed to be 12-24v system, but some tests some time ago indicated it could run 5v just fine. ESP32 runs at 3.3v, so they have a LDO conversion to 3.3v, but of course that means it needs enough voltage above that to run properly without the voltage dipping too low. Well, apparently there is a diode on the board which is dropping it an additional 0.6V (along with other components) before it hits the voltage conversion sub-board. So when it starts up, the WiFi immediately starts up, and it sags the voltage to 3.11v and the thing browns out. So the sellers solution is to jump (short) the one diode which should let the voltage be back up high enough to run properly.

This way to use diode was adopted a long time ago for all our boards to reduce voltage input on LTO and then power dissipation in LTO that may burn when we need up to LTO limit (about 1 amp.) , in this case, you don’t really need that, remove or shunt it with confidence.

So yeah. Chinesium can be great, but then you run into trouble like this that just wastes your time.

So I’ll update here when I have some visible working hardware so ya’ll can see, but thought I’d share the tale of woes as well as cool F/OSS stuff for those that like pretty lights. There’s also a WLED Home-Assistant integration for those that run HA for smart home stuffs.