Recently, my ongoing dreams of being able to repair, make or modify every tool and gadget around me met with my goals of abandoning as much proprietary software and hardware as possible by discovery of the yarh.io project. Aka [Y]ET [A]NOTHER [R]ASPBERRY [H]ANDHELD.

It’s a project to make hackable raspberry pi 3 devices in 3D printed housings. I don’t know what ‘another’ handhelds they’re referring to because I’ve seen few others beyond retro-pi gaming handhelds and I think this is by far the most mature project I’ve seen yet.

It is still like most open source projects in that it’s documentation is a bit lacking. CAD files are not available, only the .STLs. Code for the Arduino pro micro in the MK2 seems completely missing. So some parts of this project are likely to be a bit open to personal interpretation.

So, here’s the start of an ongoing build log of putting some together and seeing what they can do. Some initial hardware is ordered, including some more filament spools. I figured to start printing the MK2, but it seems worth playing with both and seeing what features and form factors work best.

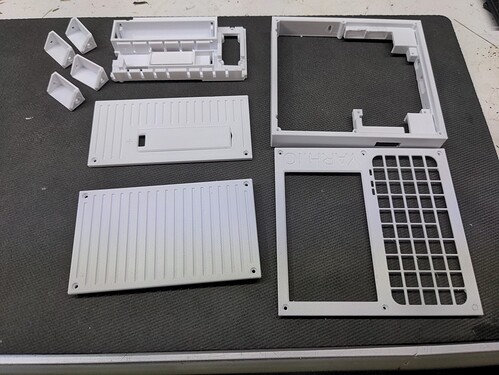

Here’s all the parts for the first one:

Everything fits together very well. I seem to lack the right size 2-56 screws to put it together, so those are on order. Here is a test fitup:

These will be more visually distinct in the near future, as I plan on printing parts in different colors for more interest. Personally, I quite like the color scheme of devices found in the

Subnautica universe, so this will probably get a mix of grey and orange parts added on to it. Some prefer all black and more power to them. I can print those as soon as my new spools arrive.

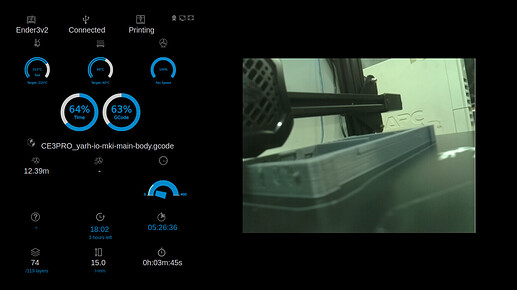

As I type the backplate for the MK1 is printing, and I can give a first impression of the difference in feel between the two. Just looking at the hardware, it looks like the Pimoroni ‘Hyperpixel’ display of the MK2 will be superior in it’s contrast, resolution, and capacitive touchscreen. The MK1 on the other hand has a track pad, and since the HDMI display doesn’t consume all the GPIO pins, there is room and breakouts leading into the keyboard compartment for internal expansions.

The MK2 would be limited to USB devices for the most part, but I look forward to seeing what kind of brainstorming happens hear on that end. A USB sound card might run Fldigi and radio CAT control passably well. I myself want some kind of LoRa modem, likely something as found from the nice fellow at unsigned.io