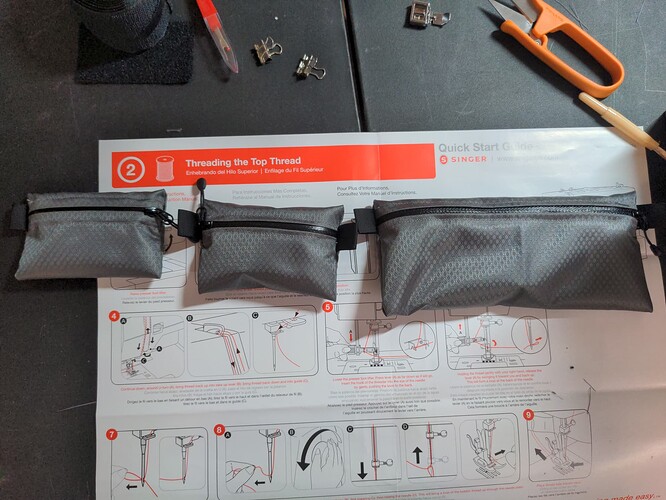

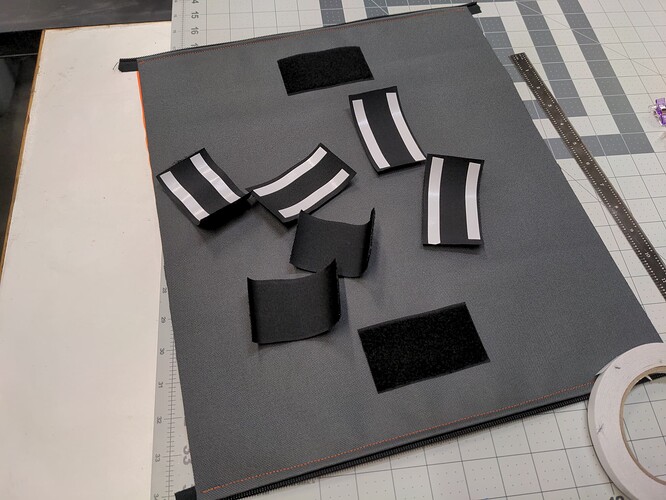

Still waiting for my latest order of zippers, velcro, etc. to arrive so I can resume more fun projects.

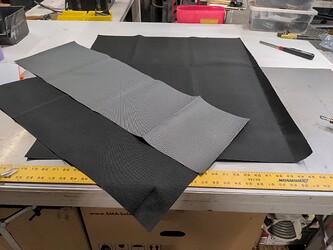

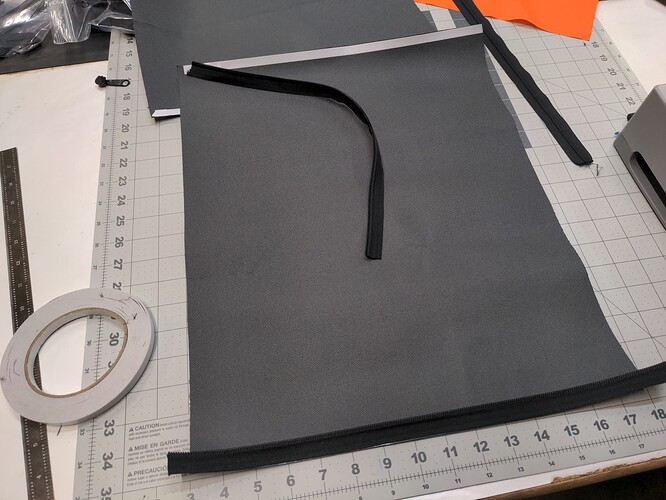

Some tests in the meantime. I started cutting some material for a larger project but I need to practice some seams first. So I took a piece of gray and black Cordura and decided to stitch it together. If it fails horribly, I’ll trim it off and try it again.

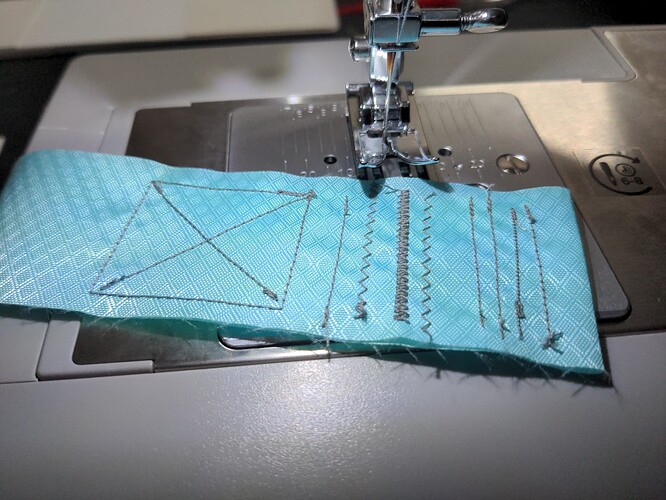

So I started by sewing the 2 parts together, wrong sides out. This was good practice, some of my first longer seams here are clearly not very straight. I’m learning how much force [and where] to apply to steer the fabric smoothly through the feed dogs without overriding them or fighting against them.

Don’t fight the dogs. I will never end well for you. There’s a metaphor in there somewhere…

So I basically made a seam with the edges standing up, then my goal was to fold it over and stitch that down. So its kind of like half of a flat-felled seam if you did it wrong and didn’t know what a flat-felled seam was

That didn’t seem super strong, and had that exposed edge on the outside. So just to get some more stitches in I tried overcasting the edge with a zigzag to see what would happen.

It was OK I guess. It kinda feels like a wide zig-zag stitch doesn’t tension like a straight stitch. I had what I thought was a good tension set, but even cranking it up it still felt a little loose on the second zig-zag. This is after a project last week where I was able to turn up a narrow zig-zag stitch up a little too much while sewing through 3 layers of polypro webbing. As zig-zag width goes up, stitch tension goes down in proportion?

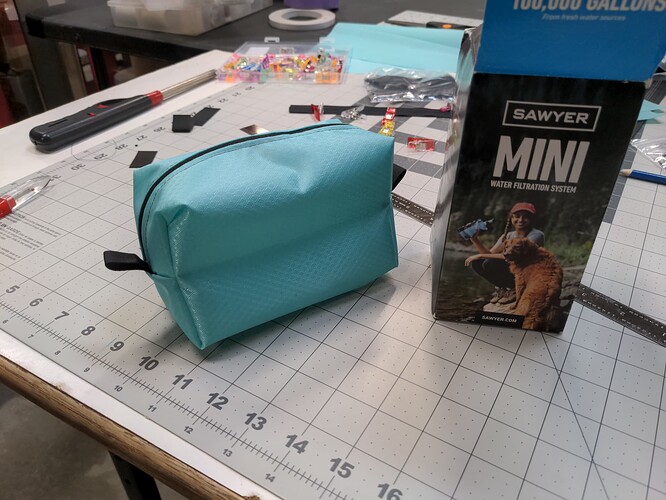

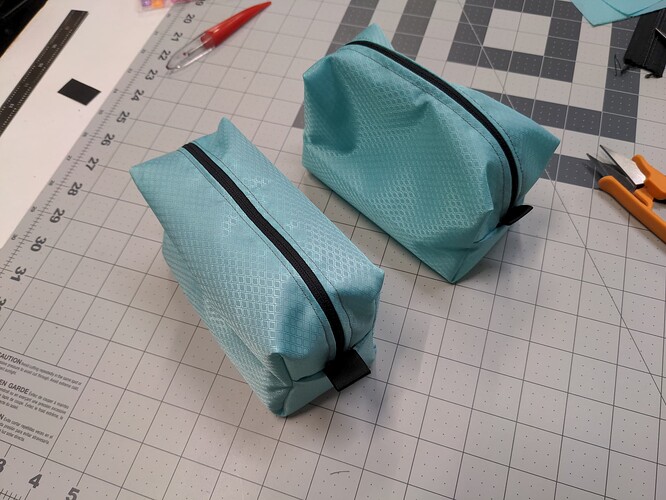

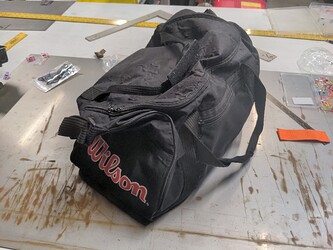

I did end up with enough of a part size to cut 18x14.5" out of it, so I think I’ll make another one of those box-bags from it and see how it holds up. Maybe I’ll use it. Maybe I’ll just fill it with rocks and chuck it around and see which stitch fails first (zipper, splice/seam, ends, or grab handle)

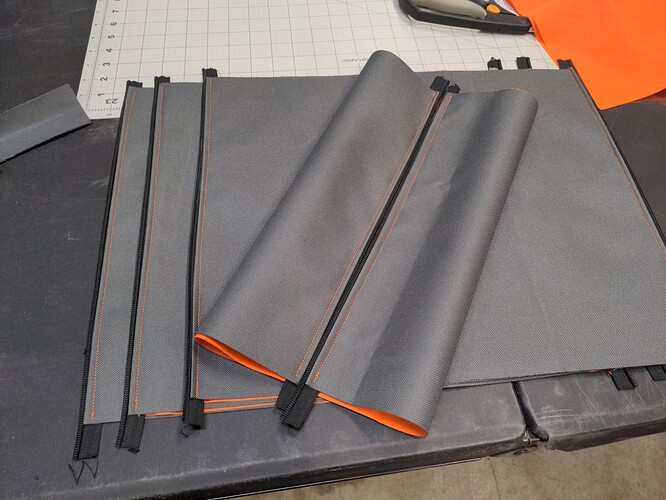

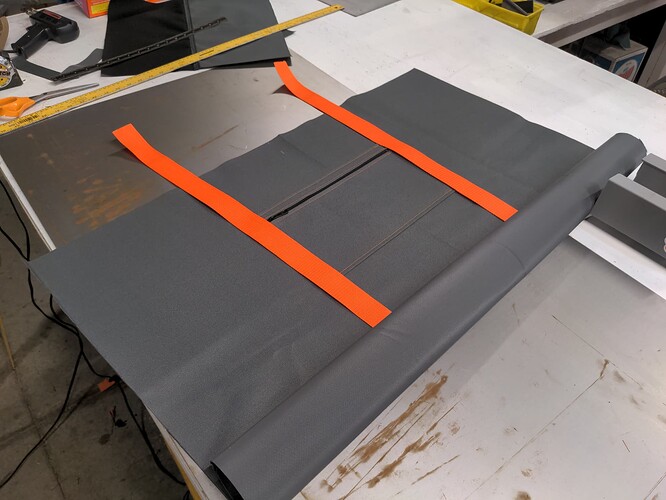

It did all work well enough that I figured to try and actual flat-felled seam next. Extra wide though, a little more forgiving on alignment that way.

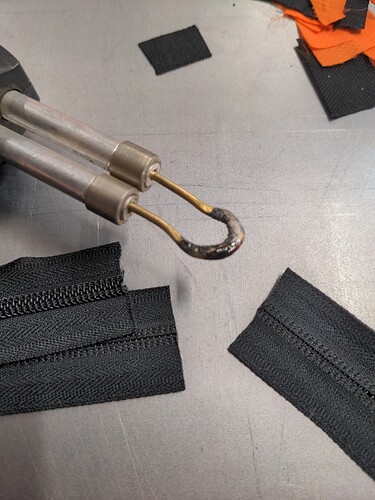

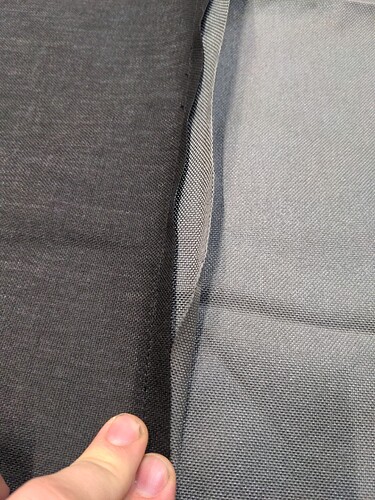

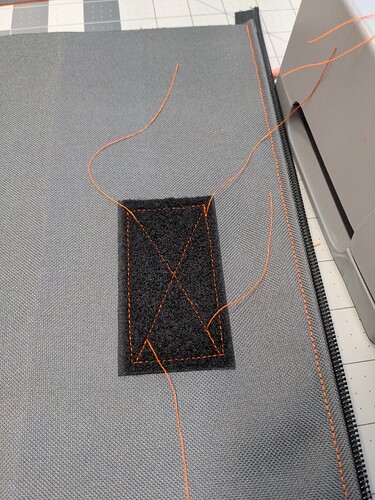

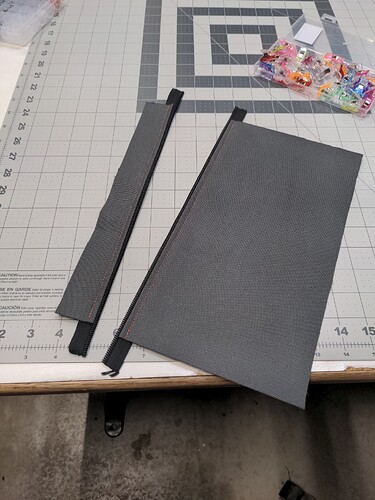

So you stitch the edges together, outside facing together, then trim one side of that back halfway. The black side in this case.

Then you fold the long-side into the center, then the whole thing will get folded over to the left. Then stitched. This encases the edges of both edges of the fabric and makes a strong, shear resistant seam.

You’re supposed to iron the seams down in 2-3 stages to get it all tight and flat before stitching. Cordura, apparently, does not iron down very well. Or my little craft iron doesn’t get hot enough. Or I suck at folding and ironing clothing… yeah, yeah it’s probably the material’s fault. Let’s go with that.

But there’s the double row of stitching and folded over seams. Every time I do this things get a little straighter, or at least smoother. There’s just something about needing to get a feel for how large pieces feed through the machine before I make smaller, frequent adjustments instead of large course corrections when things get off track.

It does feel quite strong though! I’ll see how this turns out as another box bag once more coil-zipper arrives.