Except for paint and a couple 5/8" washers I forgot to buy, the articulated hitch project is complete!

Ball-couplers don’t have that much range of motion when off road, and can tend to bottom out in places. Also, this looked like fun to build as an accessory for another trailer project that I hope to have postings of soon.

I didn’t actually make any drawings for this. Just looked at some pictures online and experimented with the bits and pieces I’ve got around.

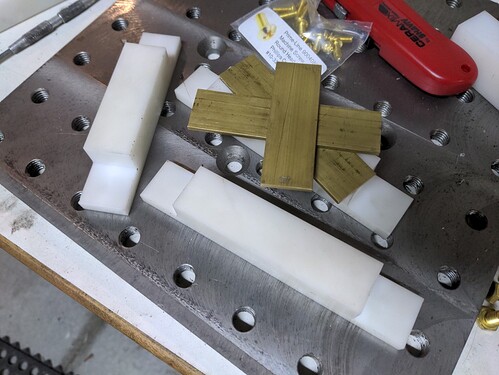

Many designs start by just stacking random stuff together, deciding how everything should fit. This hitch needs 3 separate joints for pitch/yaw/roll; essentially forming a stretched out universal-joint.

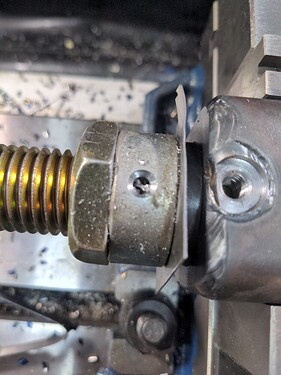

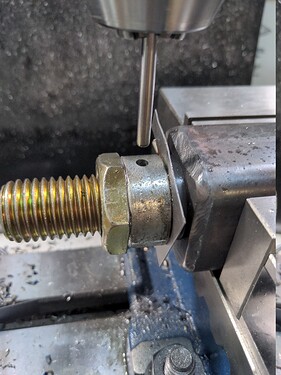

So the roll element will be brought about by this 1"-8 bolt here. Nylon bushings on both sides of a 1/2" plug that gets welded in the end.

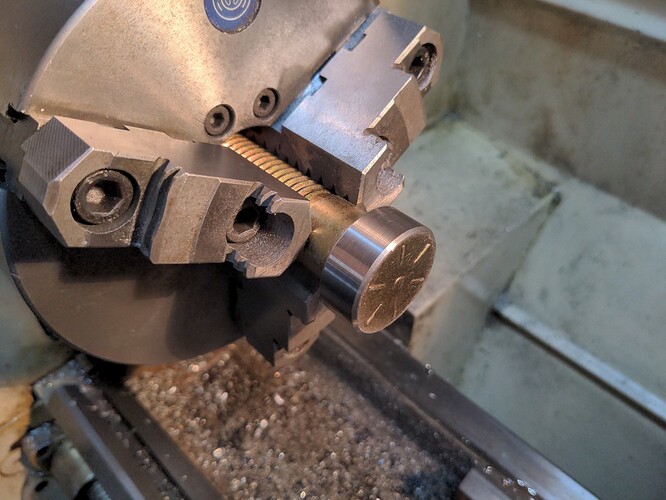

In order for that rotation to happen properly, this bolt gets the hex part removed.

So now I’ve got a stack going through the 2" box tube: Bolt → nylon bushing → plug → nylon bushing → locking collar. I shoved a piece of .030" sheet metal between the collar and nylon bushing, so I could stop the whole thing from turning in the mill, but still have clearance to rotate properly when I took it out.

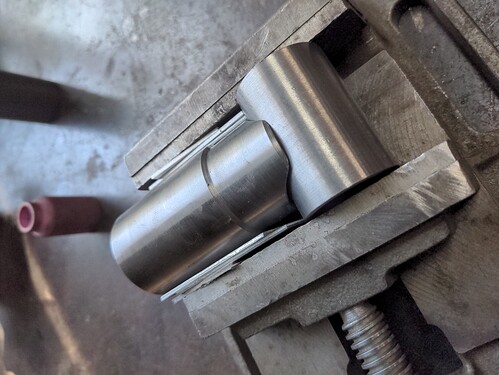

Shop tip: putting long and/or narrow press-fit pins in things can be a pain to get in straight without bending or breaking something. Use a drill chuck should at least get it started, so it’s straight and lined up before taking it to the arbor press [or vise or hammer]

So here’s that test fit into the receiver tube, which will actually be the front of the trailer.

Now for the front half. Clevis parts machined and ready to assemble.

I’d say those welds turned out alright.

Forgot to get a pictures of machining the parts for pitch movement. 1" ID tube for the cross-piece, but I didn’t have any thick wall tubing with a small enough ID to tap 1"-8, so I machined that from solid and milled a fishmouth on the front end.

Fitup in a vise for tacking. I stuffed bits of sheet metal scrap in both sides to center it up.

Then weld that at look at the pretty colors!

So this part threads onto the bolt from the rear coupler. That jam nut and lock washer are really just to keep things from feeling sloppy. In order for this thing to actually come unscrewed in transit, it would require flipping the trailer over. To the left. Multiple times.

Overthought-out hitch complete!

An example of it’s movement range. This could pull trailers places I personally don’t really want to go!

Paint soon, test later. You’ll see this again when I get to go out and test it on the trail.