So… @Canem and I got something loaded onto trailers today (pulled by Fords - all the interesting stuff I get involved in seems to include a lot of Fords).

His trailer’s an awful lot nicer than the one I use. Though I have plans to do a full refresh on the one I use, at some point.

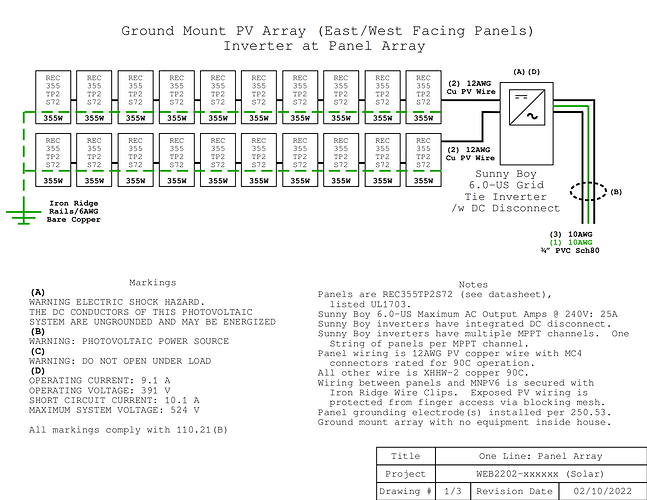

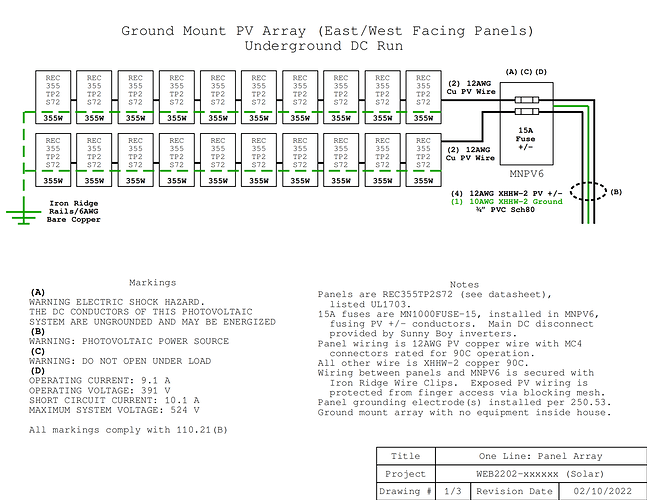

This is 35.5kW of solar panels, in the form of 100x 144 half-cell 355W panels. The plan is to build five ground mount arrays at two different locations (other people’s homes, they’ll of course be doing the electrical interconnection work on their primary residence, as allowed out here). One will be ~14kW, one will be ~21kW.

After building my arrays, the reasonable topic of “Ok, how would you improve this?” came up in conversation - and while I’m happy with my arrays, and how I did things, I can come up with some ways to improve it. The biggest is that my wooden A-frames, while fairly cheap to build when I bought lumber, are incredibly labor intensive, and are “insanely overbuilt,” to what is probably a flaw. No problems, I like things that way, but we can improve it. Especially since metalworking isn’t my thing, but I now know someone who does some properly fine metalwork and welding.

The general concept is to build ground mount A-frames, as cheaply as we possibly can, while maintaining robust structural strength and, of course, code compliance and legality. Out here, most people have land - so a ground mount array, clear of the shade, typically won’t be a problem. As a major bonus, you now eliminate any roof work, which makes things a lot more reasonable for quite a few people, myself included. Ask me to help with a ground mount array, I’m excited. Ask me to go on a roof, there’d better be a damned good reason. I’m no longer likely to bounce if I fall off a roof, I’m likely to spend some serious time in a hospital.

This thread serves as a discussion and at least partial build log thread, though. I’m digging into the design and math for a couple scenarios, and trying to optimize cost throughout. If it’s cheaper to mount the inverters to the arrays and run AC back to the house (conveniently skipping the local “understanding” about a short vertical run to the inverters), then so be it. But expect some fun NEC math here!

Goal: Two large installs built and online by the end of 2022, with much learned about how to further improve the process.