I have most of a full day’s data, and it demonstrates the difference between south facing panels and my A-frames.

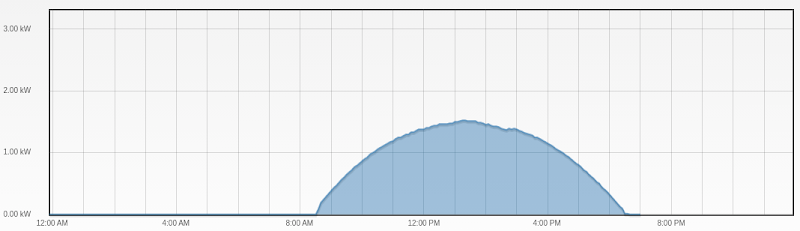

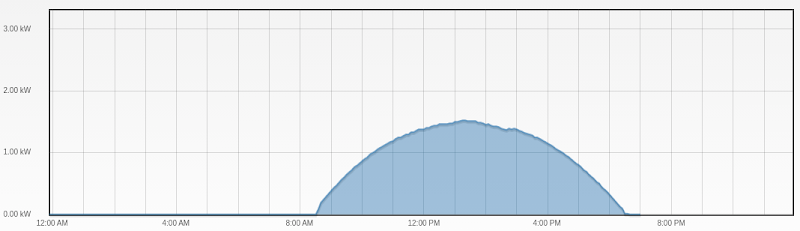

This is the south facing panel, and represents a “typical” solar facing. We’re in the wrong timezone, so solar noon is about 1:30 PM. This is 6 panels, 1770W nameplate, peak production of around 1450W or so. Today, 10.37 kWh, or 1.72kWh per panel.

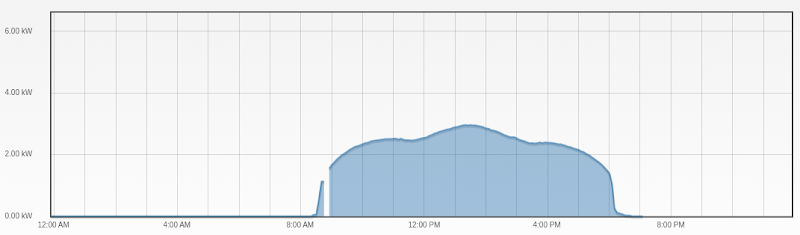

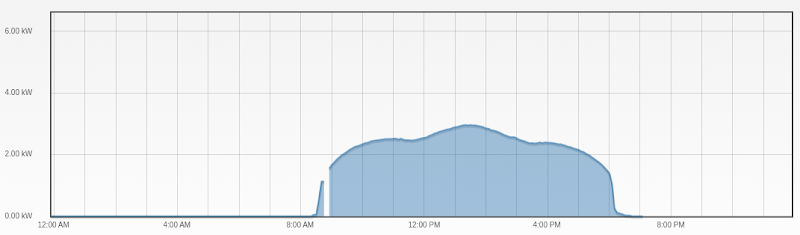

My east A-frame inverter demonstrates the perks of the A-frames - a far wider production curve. Data logging glitched briefly in the morning, but you can see how it rises to a good power rating far faster (these are twice the scale of the north frame, 6kW vs 3kW inverters), peaks around 3kW, but is above 2.5kW for most of the solar day. You can see it’s slightly “chopped” at the end of the day, and that’s shading. This frame produced 22.7kWh today out of 24 panels, so 0.94kWh per panel. The sun is rising/setting south of east/west, so there’s not as strong an advantage to the east/west panels right now, but in the summer, when the sun is rising well north of east/west, these will be online far earlier when south panels are still literally backlit. Also, on a cloudy day, panel area is king, so I can still pull energy out of the sky on darker days.

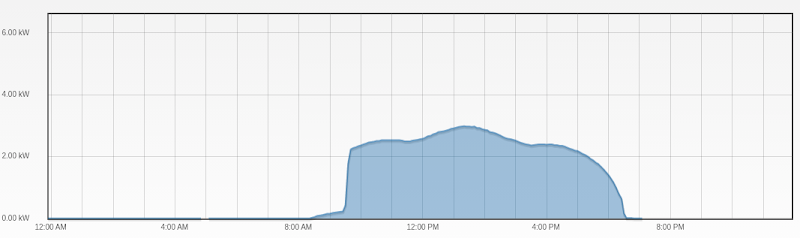

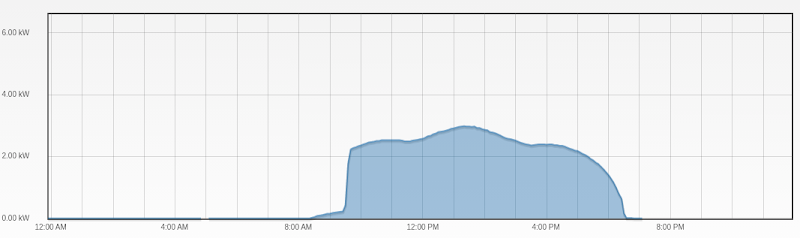

The west array is a bit lower, physically, than the east array, so has shading a bit longer in the morning. It went from 200W to 2200W over 15 minutes, give or take, as the shading disappeared. The curve is a bit smoother in the evening, as it’s not being shaded then. 21.68kWh today (because of morning shading - the two run basically identically when fully illuminated), so 0.90kWh per panel.

Again, the south panels are more efficient per panel, but the overall curve of power delivery is far flatter with the east-west panels, and they’ll really come into their own on both cloudy days and in the summer when the sun is rising to the north and is up at 35 degrees by the time it hits due east.

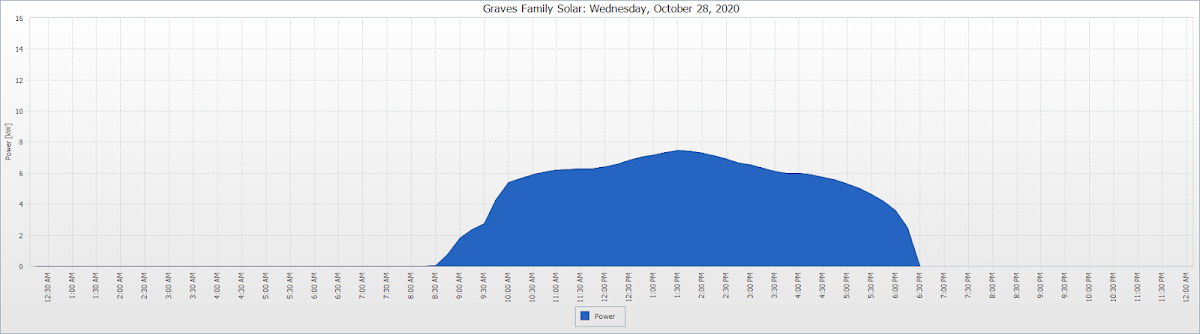

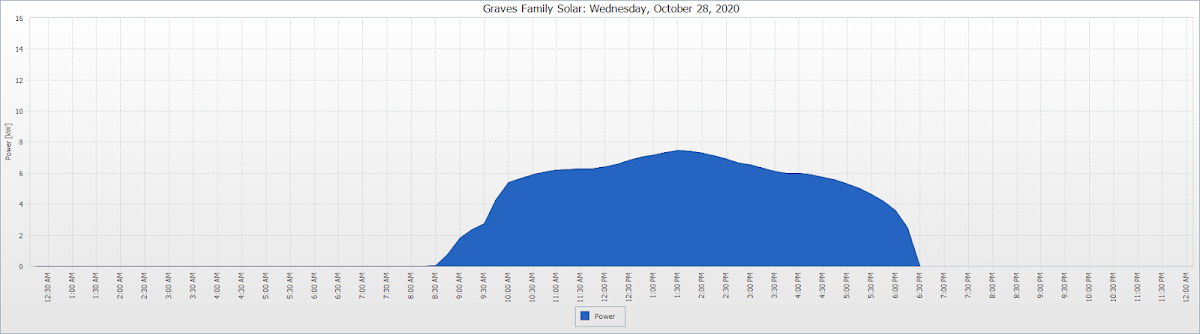

Total production looks like this…

Again, fairly flat and wide compared to a south facing curve. There’s actually a bit of a mid-day peak that was intended mostly for vehicle charging. Peak is about 7.5kW right now, but it holds 6kW from 10:30 AM to 4PM.

Total production on a clear day was 54.4kWh, which is rather substantially in excess of our daily energy use (we didn’t drive anywhere today). Trying to build up and bank hours for winter. I expect I’ll be pulling net power from the grid this winter, just because I won’t have enough time to build up the kWh bank, but I expect after next year, I shouldn’t have to pay for power for 25 years.

At this point, I basically just let it run and try to ignore it… instead of watching my power delivery curves. I may get a battery powered leaf blower to blow some dust off the panels on an occasional basis.