The new springs are worth it and I just installed this thing this week:

I actually bought it with the printer but didn’t get around to installing it yet. Until this week, when the plastic bit holding that tension bearing cracked and started to come loose. Grr…

Found that out when I decided to print this giant (and redesigned as phone holder) calicat. Those dark lines are layers that it almost completely skipped. One ear fell off and had to be glued back on. So all metal extruded setup it is.

I thought the upgrades were a good value. I think I paid $20 for a Capricorn bowden tube and connectors, upgraded bed springs, and the all metal feed assembly.

Esun PLA+ as been the absolute easiest ‘it just works’ material I’ve tried so far. Super consistent results, great adhesion, smooth feeding and flowrate. Totally worth the price. It should survive slightly higher service temperatures than regular PLA, although I believe it’s still not ‘hot car in summer’ capable. As far as strength goes though I’d put it up next to PETG from what I’ve tested so far though.

Overture ‘PLA Pro’ is supposedly the same temp and strength ratings as Esun. It works at the same temp settings but must be less dense. I got good results after I cranked the flow rate up to near 115%. Before that there were all sorts of voids and poor layer adhesion and stringing.

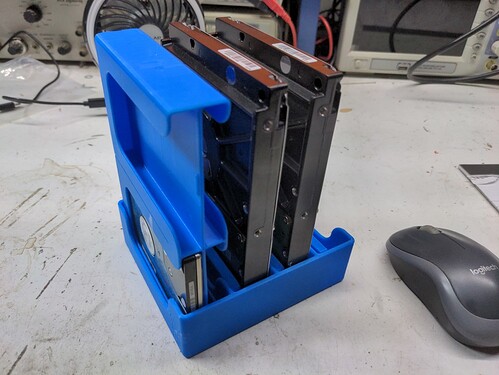

This organizer for some spare HDDs turned out great:

That temperature tower looks very handy. I’ve got some gluesticks to try next with PETG for better bed adhesion, but clearly I also need something like a temperature tower to really dial in the right settings for more consistent results.

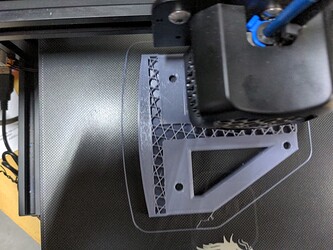

One quick CAD project was a couple wall-mount speaker shelves. I’m really impressed with how that diagonal overhang printed so well without support.

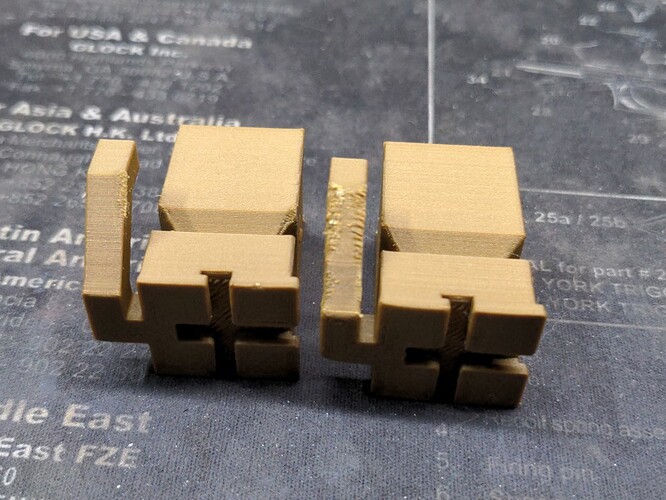

This is just an interesting look at the infill while it was still in the base layers.

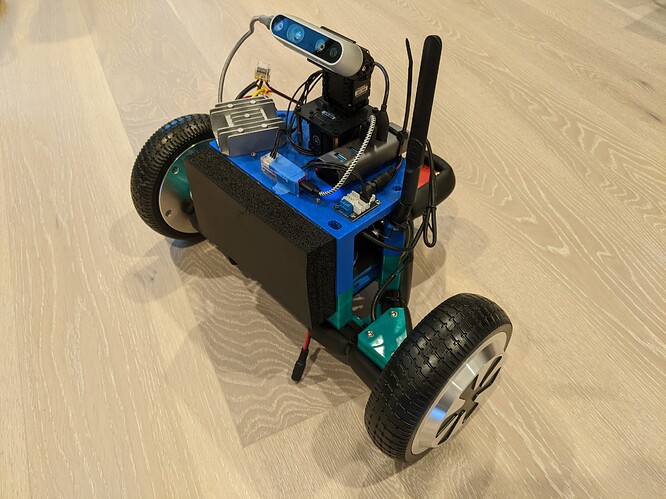

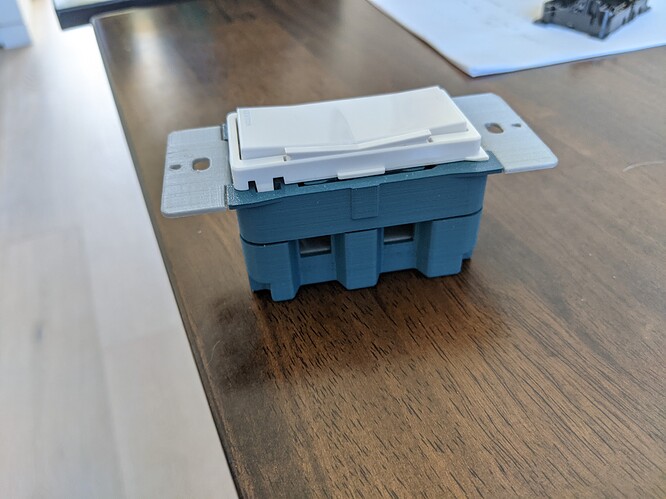

So that got mounted to look like this:

Which I combined with some downloaded cable clips to clean up my living room desk area. It’s not perfect and some of my cables are a bit too short. This is way tidier than it was though.

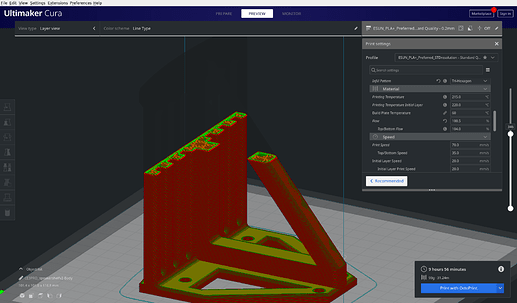

I’ve got my second test running of that shiny sort of coffee-bronze look like that failed calicat above. The second part of said test is about 3 hours into a 10 hour print, so I’ll have results of how shiny and nice looking that is later if the new tension arm solved my skipping layers problem.